Click on the follow link to find out more information: http://www.wdxmould.com/check-fixture-mould/

Company Info

- Company Name: Kunshan Wangdaxin Precision Mould Co., Ltd.

- Representative: Yang Rong

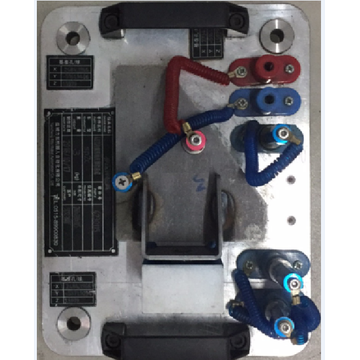

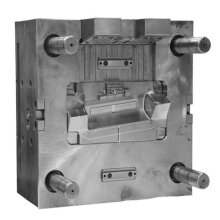

- Product/Service: Auto and Motorcycle Accessories , Photoelectric Mould , Home Appliance Mould , TV Large sizes Mold , Inspection Mold , Mold Processing

- Capital (Million US $): 3,000,000RMB

- Year Established: 2013

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 12

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: no

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: No 115 Zhuzhu Rd., Lu Jia Town, Kunshan City, Jiangsu, 215331, China

- Contact Person: Mr. Mr. Yang

- Tel: 86--57676695

Premium Related Products

Other Products

Hot Products

High Quality led light heatsink Heat sinkFactory price aromatherapy Essential Oil Diffuser Portable / Ultrasonic Cool Mist Aroma HumidifierHigh precision plastic injection machinery part with Good Quality and Better Pricecustomized punching moldBest selling hotel keyless door lock, hotel card lock management software2018 Aluminum die casting mold2016 Plastic mold plastic shell mould - zhongshan professional electronic products, plastic shell mold factory2016 Hot sale Long lifetime precision product wholesale aluminum mouldCustom injection mold productsDurable plastic mould for parts is top selling products in chinaHigh quality OEM custom top aluminium die casting partsChina import direct aluminium alloy high quality aluminum die castingChina factory wholesale new style wholesale cheap 32v fan bladeless 2017Alibaba gold supplier wholesales cheap colorful folding bladeless fan 2017New innovative products 2017 smart massage pillow can connect to appHigh quality customized nice design in mold labeling injection molding